Ukubaluleka kwe-Chip Conveyor esebenzayo kwi-CNC Machining

Funda ngee-chip conveyors

Ii-chip conveyors ziinkqubo ezikhethekileyo ezenzelwe ukususa ii-chips kwindawo yoomatshini. Zidlala indima ebalulekileyo ekugcineni indawo yokusebenza icocekile kwaye isebenza kakuhle, nto leyo ebalulekileyo ekusebenzeni kakuhle koomatshini. Ngokususa ii-chips ngokukhawuleza, ezi zi-chip conveyors zinceda ukuthintela umonakalo wezixhobo, ukunciphisa ixesha lokungasebenzi, kunye nokuphucula imveliso iyonke.

I-CNC Chip Conveyor: Icandelo eliPhambili

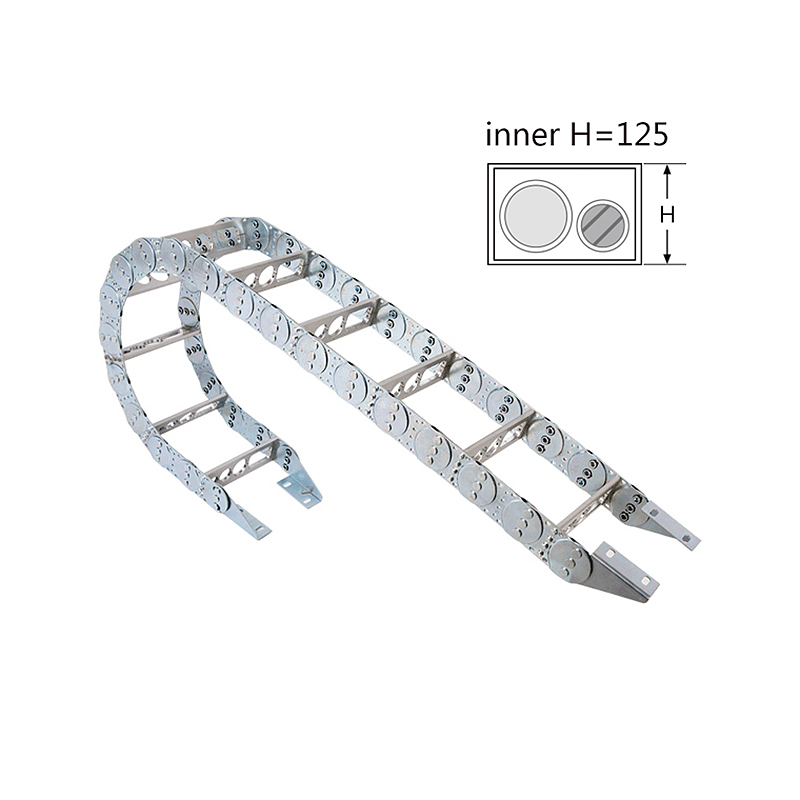

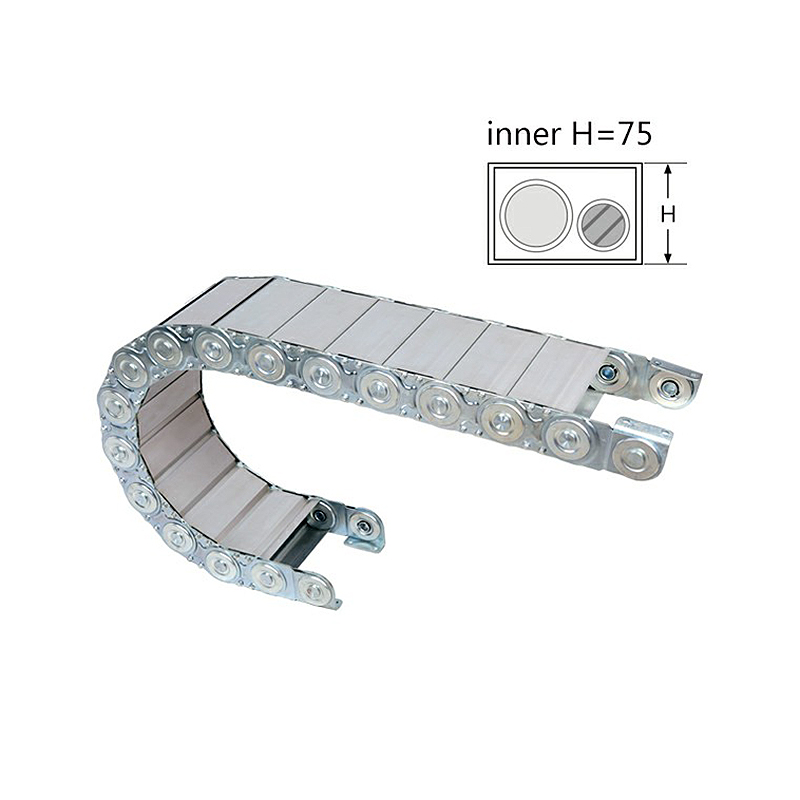

Ii-CNC chip conveyors zenzelwe ngokukodwa ukusetyenziswa nezixhobo zoomatshini be-CNC. Ezi zixhobo zokuhambisa iitshiphusi zenzelwe ngokukodwa ukujongana nemingeni eyahlukileyo ebangelwa ziitshiphusi eziveliswa ngexesha lokusebenza kwe-CNC. Zifumaneka kwiindidi ezahlukeneyo zoyilo, kubandakanya ii-conveyors zebhanti ezijikiweyo, ii-conveyors zemagnethi, kunye nee-conveyors ezijikelezayo, nganye yenzelwe iintlobo ezahlukeneyo zezinto kunye nobukhulu beetshiphusi.

Inzuzo ephambili yee-CNC chip conveyors kukukwazi kwazo ukuphatha iintlobo ezahlukeneyo zee-chip, ukusuka kwiincinci ezincinci ukuya kwii-chip ezinkulu nezinzima. Oku kuguquguquka kuzenza zibe yinxalenye ebalulekileyo yayo nayiphi na inkqubo ye-CNC machining. Ngaphezu koko, ii-CNC chip conveyors ezininzi zibonelela ngeempawu ezifana nesantya esihlengahlengiswayo kunye nolawulo oluzenzekelayo, okuvumela ukuhlanganiswa okungenamthungo kwiinkqubo ze-machining ezikhoyo.

Ii-conveyor zegumbi: isisombululo esisesinye

Nangona ii-CNC chip conveyors zisetyenziswa kakhulu, ii-scraper-type chip conveyors nazo zibonelela ngesisombululo esisebenzayo sokususa ii-chip. Ii-scraper-type chip conveyors zisebenzisa uthotho lwee-scraper okanye ii-blades ukuqokelela nokuthutha ii-chips kude nendawo yoomatshini. Olu yilo lusebenza ngakumbi ekuphatheni ii-chips ezinkulu kwaye lungasetyenziswa kwiindlela ezahlukeneyo zoshishino ngaphaya kwe-CNC machining.

Enye yezona nzuzo ziphambili ze-scraper conveyor kukuba iyakwazi ukusebenza kwiindawo ezixineneyo. Uyilo lwayo oluncinci luyivumela ukuba ilingane neendawo ezingenakufikeleleka kwii-conveyor eziqhelekileyo. Ngaphezu koko, ii-scraper conveyor zineendawo ezimbalwa ezihambayo kunezinye iintlobo zee-conveyor, nto leyo eyenza kube lula ukuzigcina.

Impembelelo yokususwa kweetships ngokufanelekileyo kwimveliso

Ukubaluleka kokususwa kweetships ngendlela ephumelelayo akunakugxininiswa kakhulu. Ukuqokelelwa kweetships kuthintela inkqubo yokwenziwa kwemishini kwaye kwandisa ukuguguleka kwezixhobo kunye noomatshini. Oku akugcini nje ngokunyusa iindleko zokugcinwa kodwa kunokubangela ukulibaziseka kwemveliso okubiza kakhulu.

Ngokutyala imali kwi-chip conveyor esemgangathweni ophezulu, abavelisi banokuphucula kakhulu ukusebenza kakuhle. Inkqubo ye-chip conveyor eyilwe kakuhle iqinisekisa ukuba ii-chips zisuswa rhoqo nangokuphumelelayo kwindawo yoomatshini, nto leyo evumela imveliso engaphazanyiswa. Oku, ngakolunye uhlangothi, kuphucula umgangatho wemveliso, kunciphisa inkunkuma, kwaye ekugqibeleni kwandisa inzuzo.

Isishwankathelo

Isishwankathelo,ii-chip conveyors (kuquka ii-CNC chip conveyors kunye nee-chain conveyors) ziyinxalenye ebalulekileyo yayo nayiphi na imisebenzi ye-CNC machining. Zidlala indima ebalulekileyo ekugcineni indawo yokusebenza icocekile kwaye isebenza kakuhle, nto leyo ebalulekileyo ekusebenzeni kakuhle kwe-machining. Ngokuqonda ukubaluleka kwezi nkqubo kunye nokutyala imali kuhlobo olufanelekileyo lwe-conveyor kwiimfuno ezithile, abavelisi banokunyusa imveliso, banciphise ixesha lokungasebenzi, kwaye baphucule ukusebenza kakuhle ngokubanzi. Njengoko ishishini lokuvelisa liqhubeka nokutshintsha, indima yee-chip conveyors ekuqinisekiseni impumelelo yeenkqubo ze-CNC machining iya kuba yinto ebaluleke ngakumbi.